Because Intelligent Compaction Measurement Values (ICMV) is a difficult subject to understand and there is a lack of systematic and comprehensive documents explaining ICMV, the Federal Highway Administration (FHWA) and pavement engineering firm The Transtec Group released a technical brief to demystify ICMV. The tech brief provides a comprehensive description on the mechanisms of ICMV and serves as a road map for using ICMV for real-time compaction monitoring, control, and acceptance. It covers how to measure and calculate ICMV, models for solving ICMV, and the various levels of ICMV.

ICMV is a generic term for advanced measurement systems instrumented on vibratory rollers as a key components of intelligent compaction (IC) systems. ICMV is based on the acceleration signals that represent the rebound force from the compacted materials to the roller drums. ICMVs are in different forms of metrics with various levels of correlation to compacted material’s mechanical and physical properties, such as stiffness, modulus, and density.

Without ICMV, it is difficult, if not completely impossible, to determine whether compaction has reached the required properties. In addition, ICMV can identify weak spots or difficult-to-compact locations even if there were sufficient roller passes for those areas. ICMV is the only technology that can provide measurements for as-built properties with 100 percent coverage of compacted areas. The tech brief provides important technical classification and level systems leading to true layer-specific modulus and density measurements of compacted materials.

ICMV helps contractors measure the levels of compaction during the compaction process to allow just-in-time adjustment of operation to optimize the compaction efforts, which leads to improved compaction quality control (QC).

ICMV provides owners and agencies with permanent records of as-built information that can be used for forensic studies and future rehabilitation decisions, which leads to improved quality acceptance and assurance (QA). High-level ICMV can also help with the future implementation of Building Information Modeling (BIM) for pavements.

Intelligent Compaction

IC is an equipment-based technology to improve quality control of compaction. IC vibratory rollers are equipped with a high precision global positioning system (GPS), infrared temperature sensors, an accelerometer-based measurement system, and an onboard color-coded display. IC is used to improve compaction control for various pavement materials including granular and clayey soils, subbase materials, and asphalt materials. The accelerometer-based measurement system is a core IC technology that was invented in the early 80’s and is still evolving today.

Over the summer, the FHWA and Transtec released two other IC technical briefs:

- Specification for Intelligent Compaction Technical Brief (FHWA-HIF-17-037) provides a review of national and state IC specifications and recommendations for future enhancements.

- Color-Coded IC Maps Technical Brief (FHWA-HIF-17-036) outlines guidelines and recommendations for color-coded maps using IC and paver-mounted thermal profiler (PMTP) data.

Veta Software

IC and paver-mounted thermal profiler (PMTP) systems gather a tremendous amount of complex geospatial data that poses challenges for data management, analysis, and reporting. These issues have become the main hurdles during implementation. To address these issues, the Minnesota Department of Transportation, FHWA, and the Transportation Pooled Fund Study, TPF-5(334) have funded development of the Veta software tool for IC and PMTP data viewing and analysis.

Veta is a map-based software tool for viewing and analyzing geospatial data. Currently, Veta can import data from various IC machines and PMTP scanners to perform editing, filtering, spot test correlation, and statistical analysis as a post-processing tool.

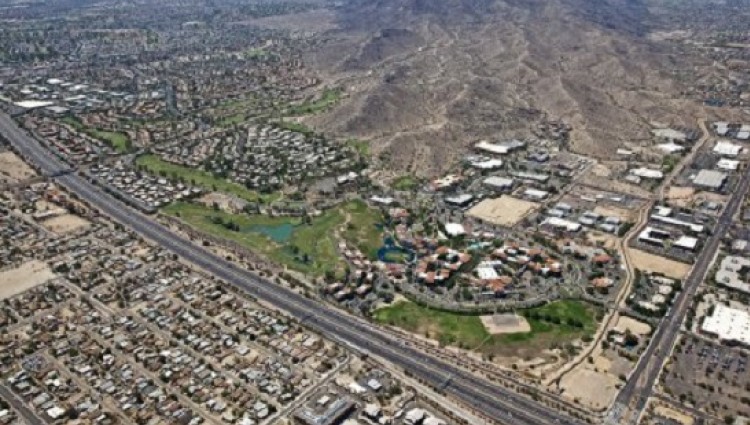

One of the salient features of Veta is to viewing IC and PMTP data as color-coded maps on top of geographical road or aerial maps to facilitate quantitative interpretation. Key examples are for evaluating consistency of rolling patterns and for identifying cold blobs or streaks of asphalt temperature segregation. Veta allows users to select any specific passes to be viewed, including the last pass or final coverage.

Veta is required in FHWA and AASHTO PP80-17 specifications, and is increasingly adopted by state highway agencies.

The Transtec Group developed Veta with support from the FHWA. Veta is free to download. Currently, the Transportation Pooled Fund (TPF) study, “TPF-5(334) Enhancement to the Intelligent Construction Data Management System (Veta) and Implementation” is leading the effort for enhancing and maintaining Veta to facilitate the national IC/PMTP implementation.